MxD’s Digital Twin Testbed for Process Manufacturing teaches manufacturers how to implement advanced technologies in their own operations.

To create the testbed, MxD partnered with Dow and Siemens, who said at the project’s 2021 launch that it allows companies to see how to design, monitor, and maintain their products more effectively, efficiently and, even remotely, using data and digital tools.

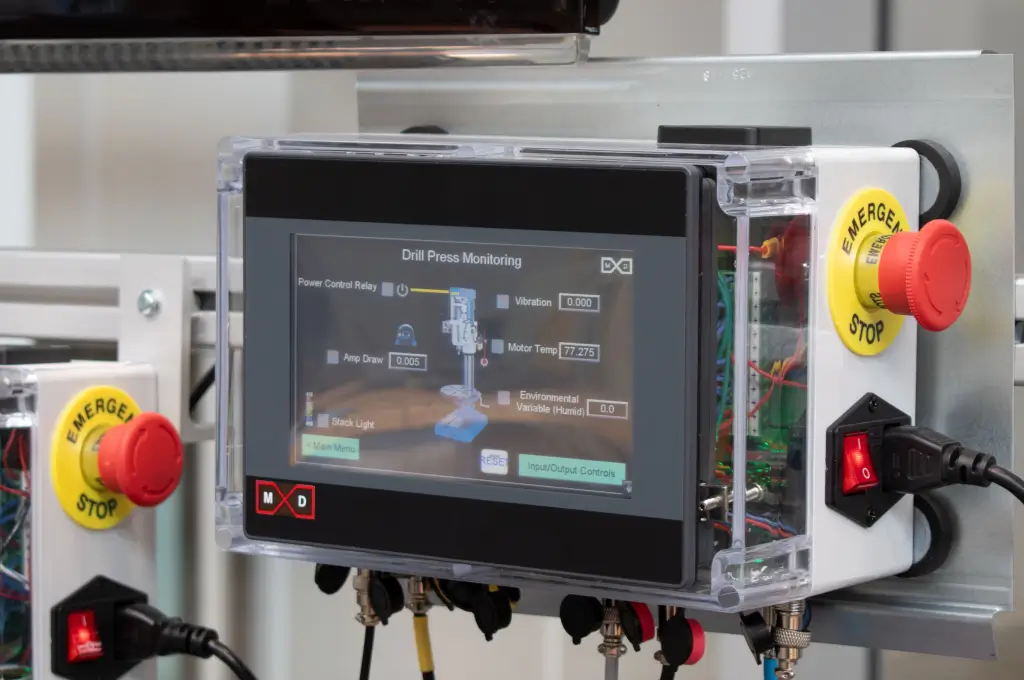

Key to the testbed is a digital twin, a virtual replica of a physical asset, process, or system that enables simulation and detailed analysis. MxD’s testbed integrates a digital twin with other cutting-edge technologies such as the Internet of Things (IoT), augmented reality (AR), and mobile worker tools to demonstrate how they can be combined with hardware to enhance process manufacturing (where many methods and workflows have remained relatively untouched for decades).

Through hands-on demonstrations, manufacturers see how digital twins can improve efficiency, reduce downtime, and enable remote operations.

In addition to developing a framework for gathering and analyzing essential data from a process manufacturing line, the testbed team created a proof-of-concept “mobile worker” solution. It shows how operators can receive tasks on a mobile device, access data needed to perform the task in the field, and update and share information immediately.

To demonstrate this, AR glasses and an industrial-grade tablet are paired with two-way video call software to display what a worker at a remote location needs to see.

The call software uses a QR code linked to the IP address of the remote device. The glasses scan the QR code to process the IP address and initiate the call software. The call information can then be displayed on the tablet or on a monitor, delivering work instructions, diagrams, or other information to a worker wearing the glasses.

AR glasses could be utilized for remote repair and safety work. For example, a supervisor could direct a maintenance worker at a job site, enabling that worker to repair a machine. Mobile worker tools can also improve safety by, for example, restricting the number of people sent into a physically challenging environment, such as a chemical plant.

The testbed serves as a dynamic lab, allowing manufacturers to experiment with the tools essential to the industry’s digital transformation.