December 31, 2023

Understanding Discrepancy Between Design and Implementation of Inventory Policies

This project investigated disparities between designed multi-echelon inventory policies and their implementation and developed ways to mitigate them by improving policy design input or providing tools for better execution.

Proposed Solution

Impact

Outcome

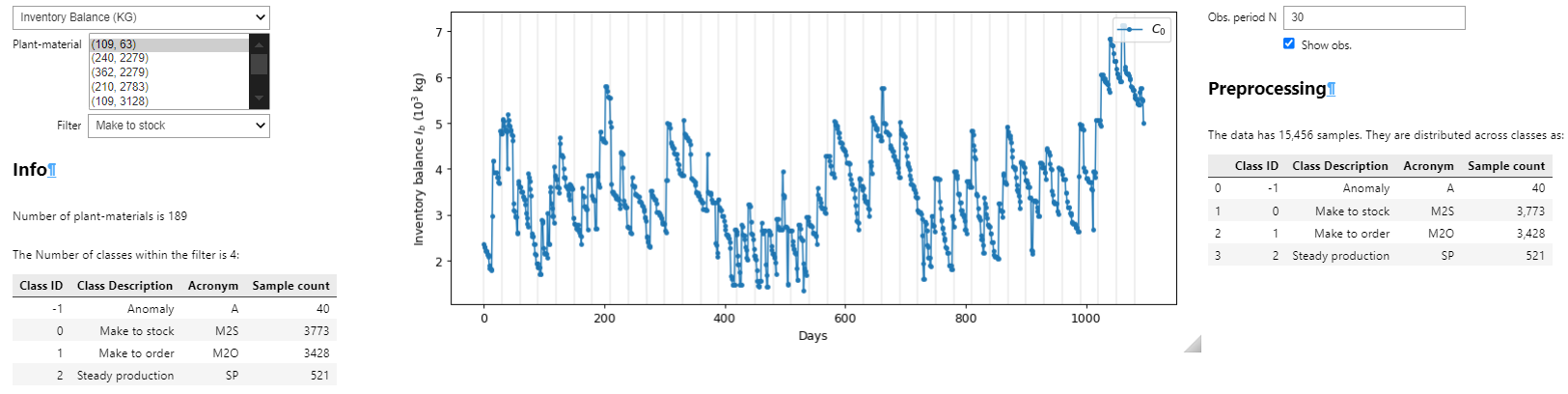

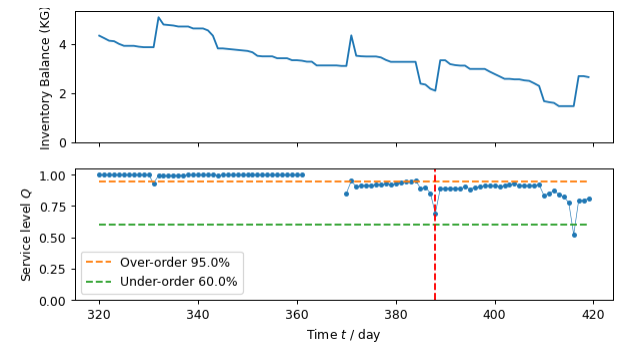

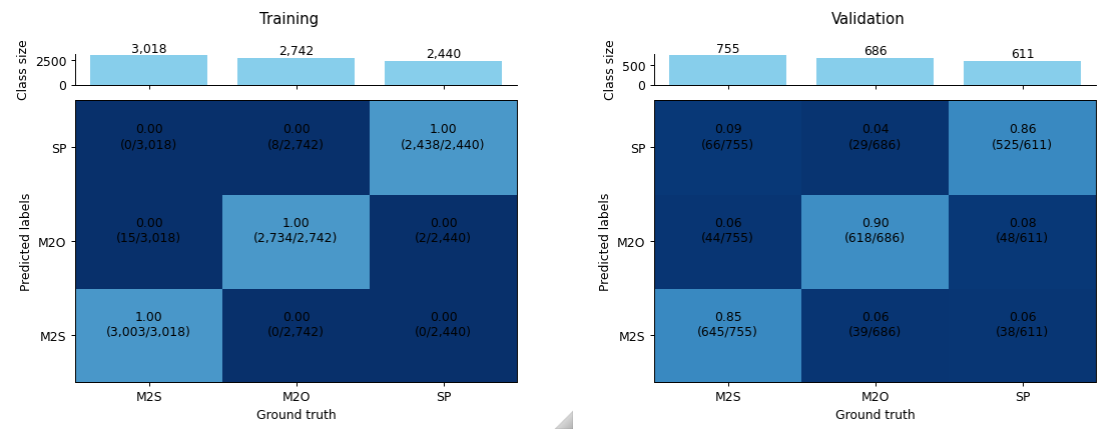

The project team developed a framework for analyzing inventory data that can detect irregularities and changes in inventory behavior as well as less-than-optimal inventory management, such as over- and under-ordering. The framework was implemented in Python and delivered as a single class within a JupyterLab notebook. The notebook illustrated some typical uses of the framework, including detecting sub-optimal inventory management.

The data used was anonymized and delivered along with the notebook so researchers could reproduce and extend the results.