July 30, 2024

Technical Data as a Service (TDaaS)

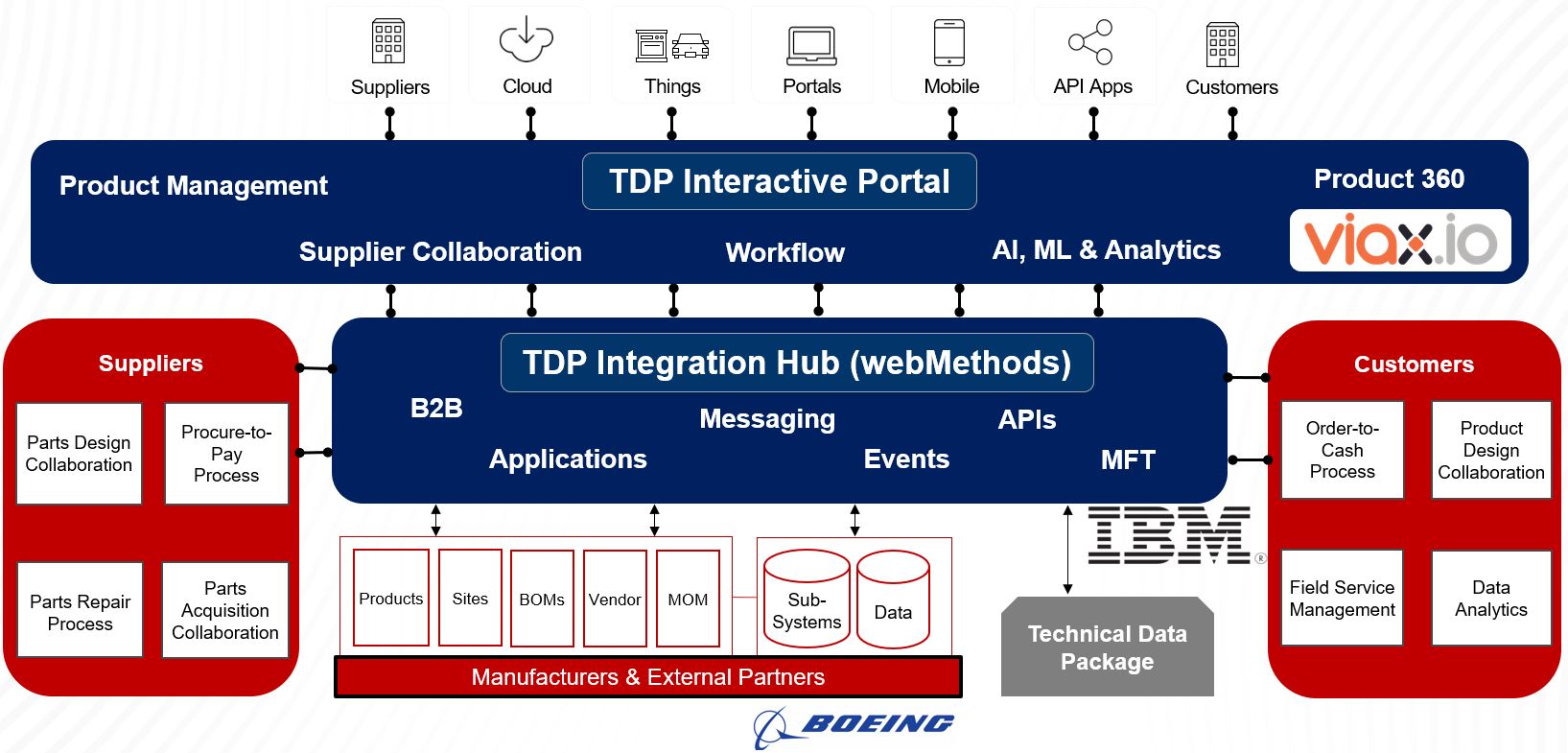

The project team delivered a prototype Technical Data as a Service (TDaaS) solution that streamlines and enhances the management and utilization of technical data packages (TDPs) for a large manufacturer and its extensive ecosystem of suppliers and partners.

Proposed Solution

By combining innovative building blocks, TDaaS provided a leading-edge enterprise grade solution that:

- Delivers a world-class TDP experience for manufacturers in a secure and personalized way;

- Provides a single accurate source of information;

- Enforces standards via an industry-leading integration framework and reduces system silos;

- Expands visibility and reach;

- And adds capabilities leveraging a platform that’s built to scale.

Impact

Outcome

The project team delivered a prototype TDaaS solution that includes TDP Integration Hub, an applications and data integration platform and framework featuring application programming interfaces (API) and powered by IBM's webMethods. It also includes TDP Interactive Portal, a user interface (UI) portal to facilitate data visualization, workflows, and business processing that is powered by viax.io. The solution established building blocks for suppliers to effectively collaborate with manufacturers.

The prototype was built around two Boeing use cases: Supplier Collaboration for Initial Onboarding and Supplier Collaboration for Production of the Part.

The solution demonstrated:

- Improved supplier interaction in the sourcing and manufacturing of an assembly, such as sharing of TDP information between the supplier and the manufacturer during the outsourcing selection process.

- Dynamic sharing of production measurements with the supplier to allow for just-in-time machining of parts for final installation into an aircraft.

- Enrichment of TDPs with production measurements, the supporting supplier machining quality information, and installation notes from the OEM. This includes direct matching to Boeing tail numbers for easy identification and tracking.